Anti-Counterfeiting Technology for Medical Devices

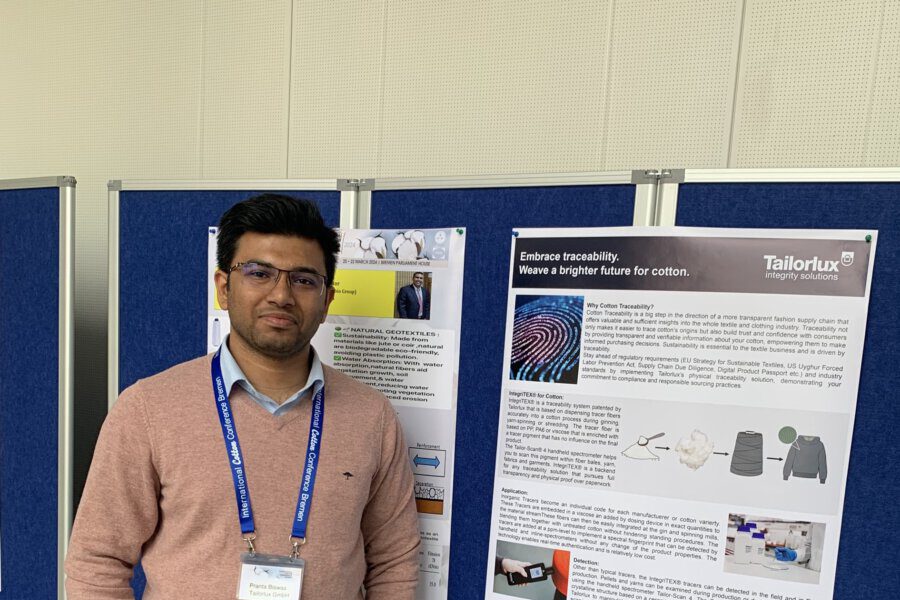

The Dülmen-based dentist Dr Bernd Johnki has equipped his patented DentureLifter with Tailor-Safe® protection. The system offers irrefutable proof of the authenticity of the product. Should Dr Johnki ever be faced with unfounded claims for damages, he now has forensically valid evidence of the authenticity of his products on his side.

Protecting Medical Technology Effectively against Counterfeits

Developing and patenting the new DentureLifter took years of Dr Johnki’s life. He invested his time, money, and passion into designing the new device that can make life easier for patients relying on dentures.

Promising innovations will often be faked and copied as soon as they hit the markets.The threat of counterfeits should never be ignored: Counterfeiters not only hurt the brand image of their victims. They steal revenue that could be used for important research and development. They are committing criminal acts that put countless jobs on the line: In Germany alone, a study by the industry association VDMA has revealed, counterfeits cost small and medium-sized businesses more than €7 billion, every single year.

Counterfeit medical devices can seriously damage the health of the patient, as they use untested materials and offer absolutely no safety guarantees.

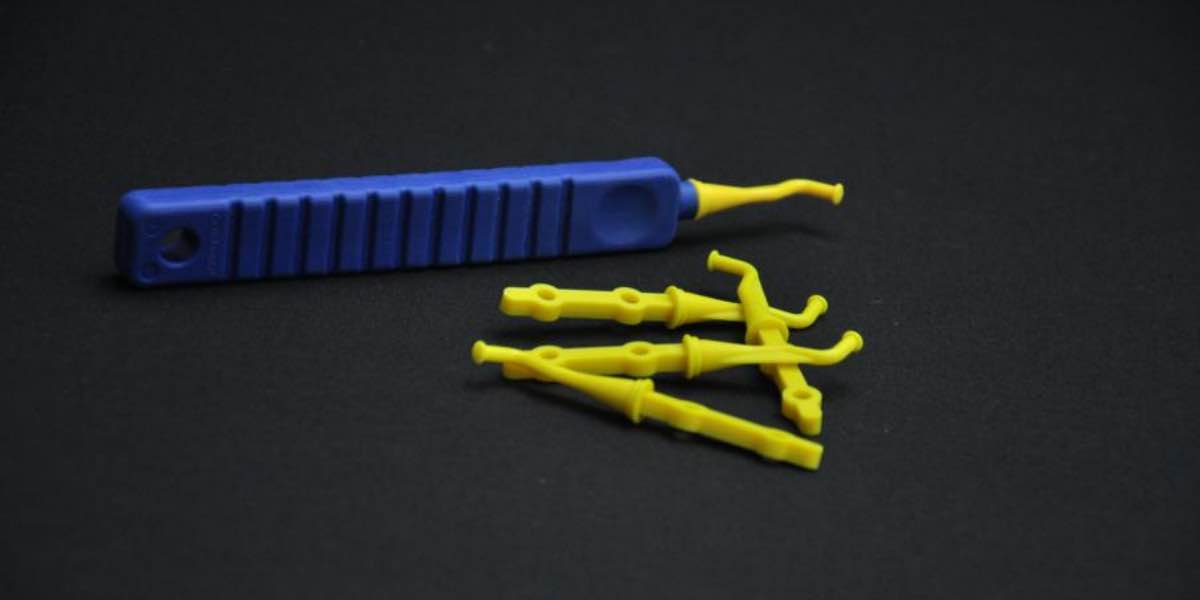

This put Dr Bernd Johnki on the hunt for a simple, but secure means of protecting his innovative dental technology against illegal copies. After a long search, Dr Johnki realized that he could protect his products with Tailor-Safe®. Tailor-Safe® is a product protection system that differs from other solutions in the market by embedding the protections right in the very material of the product. In other words: “Authenticity” becomes a built-in feature. As Dr Johnki’s DentureLifters are made from a synthetic material, the solution could be integrated simply by including it in the material’s original masterbatch.

Protection technology for medical devices is a particularly sensitive issue: The technology must never interfere with the properties of the actual product and, of course, be absolutely harmless to the health of its users. Dr Johnki was also looking for a simple way of proving the authenticity of his DentureLifters. One particular concern for him was the ability of the system to prevent any unwarranted or illicit complaints or damage claims against the company

Tailor-Safe® is a technical protection system that uses luminescent pigments to mark and authenticate products. The unique quality of the pigments makes it virtually impossible for anybody to fake or forge a Tailor-Safe® marker.

Any solution that offers effective protection against counterfeiters also needs to be commercially viable. This concerns both the cost for each marked unit and the general costs of integrating the system in the production and business processes. The anti-counterfeiting technology in Tailor-Safe® is machine-readable and can be integrated in virtually any material and substance. The solution is simple to integrate in production, and the cost of the markers lies at only a fraction of a percent of the overall product costs.

The exacting quality standards and exceptional chemical and physical properties of Tailor-Safe® make the markers reliable proof of authenticity that would stand up in a court of law when unwarranted complaints or damage claims need to be fought off. This is one of the foremost USPs of Tailor-Safe® and has been fully certified since 2013.

What good is the most sophisticated anti-counterfeiting system, if it can be worn down, scratched off, or otherwise removed? No good at all! The markers have to be indestructible, as indestructible in fact as the security pigments used in Tailor-Safe®.

Anti-counterfeiting technology for medical devices needs to live up to a very specific set of standards – which are no problem for Tailor-Safe®: The marker must never react in any way with the material it is embedded in. In other words, it has to be what chemists call chemically inert. The Tailor-Safe® pigments are not just chemically inert, they are also non-toxic and biologically neutral: the strict requirements for medical products are fulfilled by default with Tailor-Safe®.

The product markers use inorganic luminescent pigments that are as tough as granite, a property known among professionals as physical stability. Product markers with Tailor-Safe® pigments can be identified even after the product has been burned, because the pigments can withstand heat up to 1700° centigrade.

Light-Based Product Protection – An Old Hat?

Protecting products with luminescent markers is not a new idea as such. For decades, banknotes have been protected from counterfeiters with UV pigments, which are made visible by being exposed to UV light (black light). Forgers have long caught up and found ways and means to replicate these markers. The anti-counterfeiting system Tailor-Safe®, however, marks products not just with a random UV or IR marker. Each marker is unique in its type, composition, and production. The product can be authenticated not “simply” by exposing the marker to some light source. Only the right Tailor-Safe® spectrometers will tell the fakes from the originals, with nanometre accuracy: Not the marker that shines is real – only the marker that shines correctly is real. The Tailor-Safe® spectrometers learn the unique luminescent fingerprint of the marker and flag anything as a forgery that does not match the specifications.

You can find more information about technical anti-counterfeiting measures on our homepage.

You might also be interested in